The Science of Wine

I don’t know all the science behind winemaking. But my favorite Sonoma winemaker, ex-professor of particle physics Dr. Chris Loxton, sure does. After years in academic research, Chris returned to his Australian winemaking roots and started his own business in Sonoma Valley in 2001.

“When I was an experimental physicist I would make lots of observations and then try to rationalize them to find out what they meant. The same thing happens in winemaking,” he said in an interview with the Institute of Physics. Chris has applied his scientific background to understand and improve the conventions and superstitions of the winemaking process. The result is some of the most delicious wine I’ve ever tasted.

Every visit to Loxton Cellars, a simple warehouse filled with wine barrels, is a nerd’s paradise. Just mention that you have a background in science or engineering, and Chris will tell you about the latest developments in wine barrel technology and grape breeding, how understanding the Kreb’s cycle can optimize early steps of grape fermentation, or how a simple German filter can produce wine with a French flavor but American texture. Once a scientist, always a scientist.

Advances in wine barrel technology:

Wine barrels have been made the same way for the last 700 years. Oak was chosen based on its origin and grain, steamed and bent into metal staves, and fire-toasted by master coopers who decided how hot to burn the fire and when to close the lid and smoke the wood. Basically, the process was a craft based on trial and error and experience.

Fast-forward to 2014, when World Cooperage, a family-owned wine barrel business established in 1912, announced its infrared toasted barrels at the Unified Wine & Grape Symposium in Sacramento, California. Integrating barrel toasting with infrared spectroscopy and control engineering, they now have a series of barrels with a reproducible toast profile.

Because the amount of toast on a barrel has a huge impact on the flavor of the wine it holds, the variability of traditional toasting has produced variable wines. Even when a winemaker found the perfect barrel, its flavor faded with each year of winemaking. The new infrared technology controls and measures the exact amount of toast, producing an unlimited supply of identical barrels with characteristic profiles. For winemakers, this provides the opportunity to buy identical copies of that one perfect barrel that produced an award-winning wine.

For a scientist like Chris Loxton, this also means eliminating one of the many variables of the winemaking process: “In physics… you have a lot of control. You vary one thing, watch what happens and then try to reproduce it. In winemaking, you have to deal with the weather and [other] variables [that] are all changing… When you taste what you’ve made, you try to rationalize it, but it’s almost impossible. The system is too complex.”

Sources: Chris Loxton, Institute of Physics, WineBusiness.com

Genetic modification of wine grape species:

With the current atmosphere of negativity that surrounds genetic modification, winemakers can’t afford to use laboratory genetic modification to produce disease-resistant grape vines and risk losing customers. So they rely on traditional methods of genetic modification instead.

Vitis vinifera, the species of grape used to make wine, is native to the Mediterranean region. North America has its own native species, Vitis labrusca, which is adapted to local conditions and resistant to local diseases but is not used in large scale commercial winemaking. One of the challenges that Californian winemakers face is growing vines native to Europe – such as Chardonnay, Riesling, Pinot Noir and Merlot – in dry conditions and in the presence of local fungal diseases such as powdery mildew.

American viticulture – the science and production of grapes – has relied on hybrid cross-breeds of European and American varieties to achieve European flavor with American hardiness. Mixed hybrids are given names of their own, but to produce a classic European wine in America, vineyards will have to back cross the hybrids for many generations back to the European vine, carefully selecting for the disease-resistance gene while returning all other characteristics back to the original. As anyone working with laboratory mice will know, this process can take as many as ten generations and is laborious and extremely time-consuming.

While a quick introduction of the crucial gene would take a day of work in the laboratory, cautious grape growers are relying on the slow path (for now). Agriculture and viticulture programs at Cornell University and UC Davis have worked to develop disease- and weather-resistant varieties. Cornell’s grape breeding program has produced 56 new varieties since 1885. The latest two, Aromella and Arandell, were named and released in 2013.

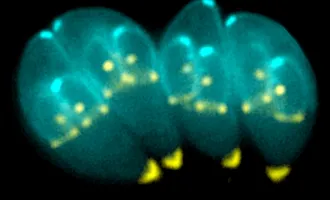

The development of new grape varieties doesn’t stop at the trial and error process of crossing plants and observing the result. Scientists use modern molecular techniques to study all aspects of grape vine biology. For example, a recent publication in the February 2015 issue of American Journal of Enology and Viticulture from Andrea Campisano and colleagues used DNA sequencing to quantify the bacterial diversity on wild and domesticated grape vines, and identified a four-fold decrease in diversity on domesticated plants. Perhaps understanding the microbiome of the grape vine could lead to new ways to protect them from disease.

As usual, it seems that the microbiome might be connected to just about everything.

Sources: Chris Loxton, Cornell University, UC Davis, American Journal of Enology and Viticulture